Bak Gravür Customer Portal

Bak Gravür Customer Portal enables our customers to monitor the status of their orders 24/7, follow up their digital approval processes and amendment requests via the portal, monitor and report the status of their cylinders in stock, and get information about the deadlines of their orders. With Bak Gravür Customer Portal, which works integrated with Bak Gravür Production System and provides transparency, convenience, comfort and privilege, our customers are in control 24/7!

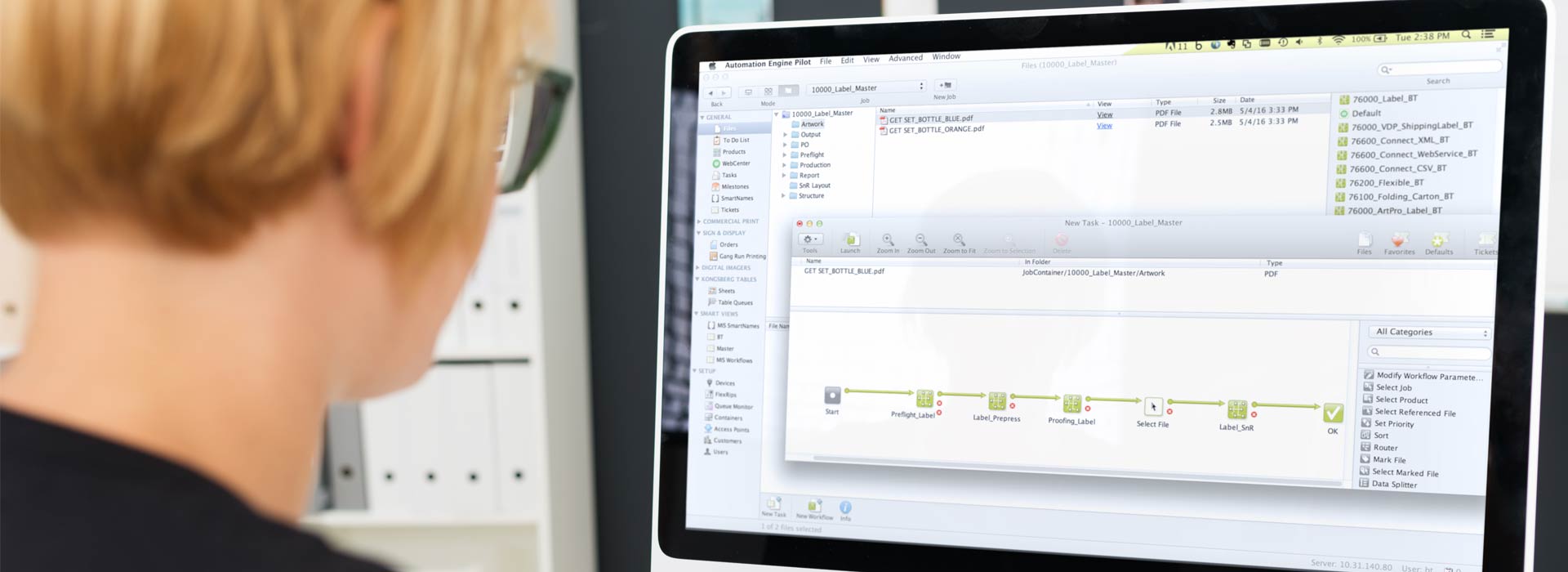

Automation Engine

Bak Gravür provides superior quality products and services to its customers and continues to create value as always by using the automation software Esko Automation Engine, which allows users to pre-set repetitive tasks in the pre-press preparation workflow and make automatic decisions in the workflow, and minimizes errors with the contribution of special quality control tools.

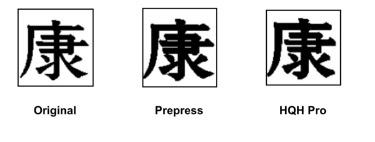

HQH

HQH is a software designed to optimize data for a better gravure printing quality. Thanks to intelligent software algorithms, it scans the original state of the digital and makes changes on the pixels that create fine text and lines, making them more legible and sharp. It minimizes the printing problems especially in reverse-text designs. Bak Gravür Preflight team holds preflight meetings with the technical team for each new design and reviews the HQH applications that will facilitate the printing processes of their customers.

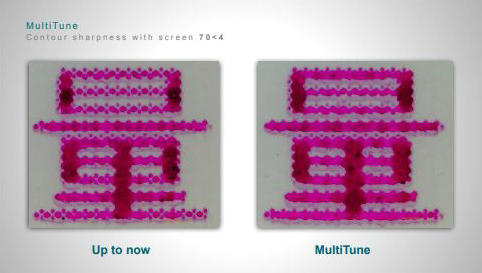

Multitune

The MultiTune adjustment process was created with the aim of providing a much more descriptive fingerprint on the engraving system than was previously possible. It allows the digital to be adapted more precisely to the respective screen/angle in order to achieve sharper contours.

Kodak NX Digicap

Kodak Flexcel NX technology ensures that the photopolymer plate is deoxygenated, resulting in flat-top screening. It provides high quality printing with 300 lpi and 0.4% - 99% dot range. In addition, it has a special screening software that can be used on backgrounds and in all tonal ranges in order to increase print quality and density. Bak Gravür will provide its customers with quality, consistency and continuity in their printing processes with this technology.

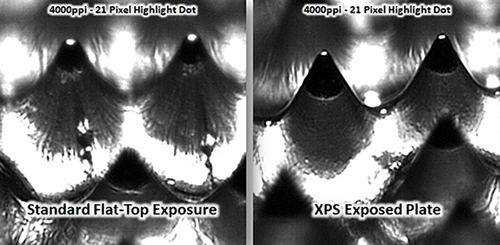

Esko CDI 5080 XPS 'Crystal' Screening

In addition to Pixel+ and Print Control Wizard (Crystal Screening) and additional software solutions with more precise higher resolution screens, Esko HD Flexo allows for high-quality plate making with additional screen shapes such as flat-top dots thanks to the combination of the Esko CDI 5080 digital flexo plate exposure machine with the XPS Crystal LED UV exposure machine. Bak Gravür will provide its customers with quality, consistency and continuity in their printing processes with this technology.